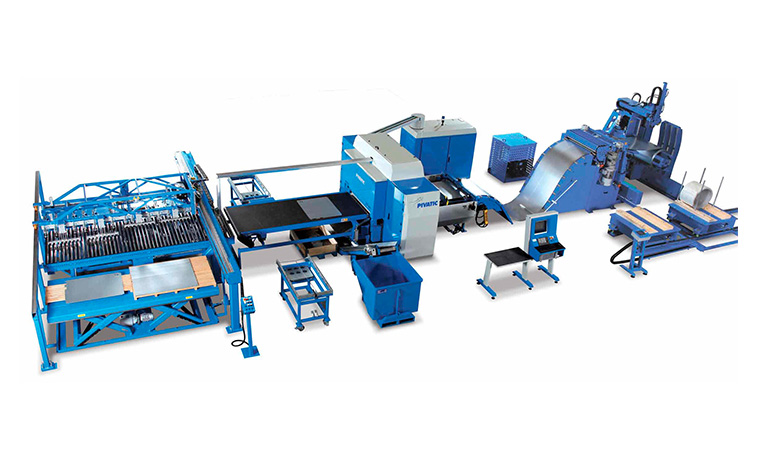

Pivatic “PivaPunch” punching lines

PivaPunch is based on standard Thick Turret Tooling set in quick-change tool cassettes on both sides of the strip. Tasks like notching, embossing, perforating and louvering can be carried out by customization. PivaPunch is designed for steel thickness up to 6 mm. Implemented for strip width up to 1830 mm. PivaPunch is more efficient than other sheet metal punching methods because it works straight from coil fully automatically, producing punched blanks stacked the way you need them. It's more flexible because it uses an advanced and freely programmable CNC coil punch system. Common coil width is used for a variety of parts produced in small batches, whereas true coil width is used for large series.

Advantages of the PivaPunch line:

- 100% of time is actual punching since there is no tool change time (all tools are active) and the strip is fed non-stop from stroke to stroke

- Double Tool Punch (DTP) feature: two holes or corners of a symmetrical pattern punched at the same time to minimize the cycle time

- No dead punching zones, no skeleton required

- No loading time with continuous coil feeding

- No unloading time with the stacker, stacking of punched blanks occurs during punching time

- No waste of material when using the True coil widths

- Includes enough tools to manage common coil width utilization