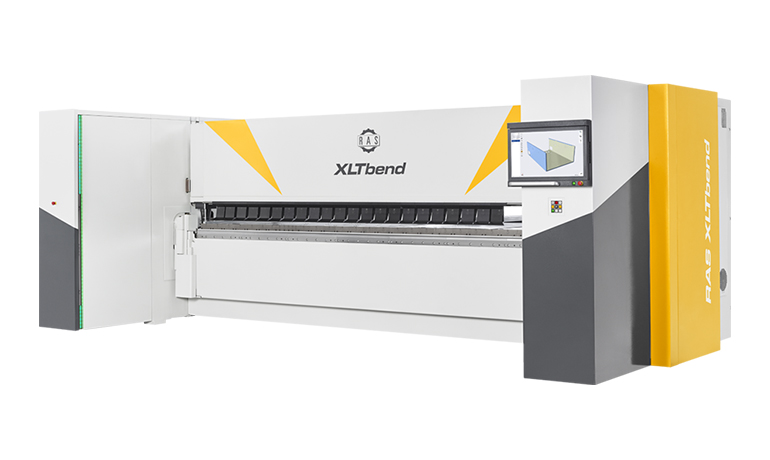

XLT Bend Folding Machine

For those who want to form complex precision sheet metal parts like cassettes, panels, and boxes profitability even in small batches, the XLTbend is a perfect fit. The XLTbend is a incredibly flexible UpDown folding machine. The revolutionary one-click programming software, front and rear operating options as well as the hybrid gauging system are outstanding features of the XLT series.

| Technical Data XLTbend (mm) | RAS 71.40 | RAS 71.30 |

| Working length | 4060 mm | 3200 mm |

| Material thickness max (400 N/mm²) | 2.5 mm | 3.0 mm |

| Upper beam open height max | 650 mm | 650 mm |

| Box height max (four-sided) | 300 mm | 300 mm |

| Gauging system | Hibrid | Hibrid |

| Programming | automatic | automatic |

| Automation | high | high |

| Bending direction | up and down | up and down |

| Parts | Profiles and boxes | Profiles and boxes |

XLTbend Highlights

- Easy operation: Part rests on gauging system

- Also thin and flexible blanks can be easily handled

- Semi automatic part handling. Safe and ergonomic operation

- A single person can even bend large and heavy components

- Operation from folding beam side (smaller parts and profiles)

- Operation from gauging side (large panels)

- Automatic part programming

- SnapTools: automatic retraction from side flanges

- ViN (Virtual Navigator): shows the part loading position

- Support function: Bending of smaller parts from the gauging side

- Ideal solution for users with high demands on flexibility

- Solution for small and medium budgets